Yesterday I got my Winhao Duplicator i3 and when I was setting it up and adjusting the print bed I thought: “Is it supposed to be like this?”

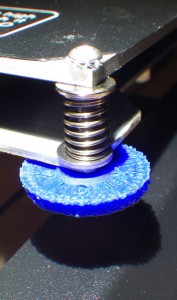

The print bed is a heated aluminum plate which is mounted on top of the Y-axis sled by four M3 screws, one in each corner. These screws compress a spring which presses the bed upwards towards the print head, while a wingnut underneath the sled forces the bed down. You level the bed by checking for an even spacing between the print head and the bed in the four corners, adjusting the spacing with the wingnut.

However, if you turn the wingnut the screw also rotates, because it is not secured in any way, only by the tiny amount of friction between the screw head and the top of the aluminum bed plate.

But it would have been so easy, to fix the screws, so after printing the second improvement, a set of thumb screws to replace the wingnuts, I also fixed the main problem.

An M3 nut easily fits inside the spring, so no additional vertical space is needed. Additionally I added a shakeproof washer between the screw and the top of the plate. Now leveling the bed is a piece of cake.